copper pipe size chart pdf

Copper Pipe Size Chart PDF: A Comprehensive Guide (Updated 12/03/2025)

Today, December 3rd, 2025, access a vital Magnetic Copper PDF (384 Kb) detailing unique interactions; Adobe Acrobat is needed for viewing this fascinating resource․

Proper copper pipe sizing is fundamental to efficient and reliable plumbing, heating, and cooling systems․ Utilizing a copper pipe size chart PDF ensures optimal fluid flow, minimizes pressure loss, and prevents costly issues like water hammer or insufficient supply․

Selecting the correct diameter isn’t simply about matching the fitting size; it’s a calculation based on flow rate, pipe length, and the number of bends․ A well-chosen size balances material cost with performance․ The December 3rd, 2025 update reflects current industry standards and best practices․

Furthermore, understanding the interplay between pipe size and magnetic properties – as detailed in supplemental PDFs like the Magnetic Copper PDF (384 Kb) – can be surprisingly relevant in certain specialized applications․ Accurate sizing, guided by a reliable chart, is paramount for long-term system integrity․

Why Use a Copper Pipe Size Chart?

A copper pipe size chart PDF is indispensable for professionals and DIYers alike, offering a quick and accurate reference for selecting the appropriate pipe diameter․ It eliminates guesswork, preventing undersized pipes that restrict flow and oversized pipes that increase material costs․

These charts consolidate critical data, including outside diameter (OD), inside diameter (ID), and wall thickness, streamlining the design and installation process․ Referencing a chart, especially one updated to December 3rd, 2025 standards, ensures compliance and optimal system performance․

Beyond basic dimensions, understanding the nuances – potentially linked to magnetic interactions as explored in the Magnetic Copper PDF (384 Kb) – contributes to a more holistic approach․ Utilizing a chart minimizes errors, saves time, and ultimately delivers a more efficient and durable plumbing system․

Types of Copper Pipe

When consulting a copper pipe size chart PDF, understanding the different types is crucial․ Rigid copper pipes – Types K, L, and M – vary in wall thickness, impacting pressure ratings and cost․ Type K is the thickest, suitable for underground use, while Type M is the thinnest, often used for interior drain, waste, and vent systems․

Flexible copper pipe offers easier installation in tight spaces, though its sizing differs slightly from rigid types․ The December 3rd, 2025 charts will detail these variations․ Remember, even considering the unusual magnetic properties detailed in the Magnetic Copper PDF (384 Kb), proper sizing remains paramount․

Selecting the correct type, guided by the chart, ensures the plumbing system meets safety standards and performs reliably․ Charts often categorize dimensions by these types, simplifying the selection process․

Rigid Copper Pipe (Types K, L, and M)

A copper pipe size chart PDF clearly delineates the specifications of rigid copper – Types K, L, and M․ Type K, with its thickest wall, is ideal for underground applications and high-pressure systems․ Type L offers a balance between durability and cost, commonly used for interior water supply lines․

Type M, the thinnest, is suitable for lower-pressure applications like drain, waste, and vent systems․ The December 3rd, 2025 charts will specify exact dimensions, including outside diameter (OD), inside diameter (ID), and wall thickness for each type and nominal size․

Even considering the intriguing magnetic properties outlined in the Magnetic Copper PDF (384 Kb), selecting the appropriate rigid copper type based on the chart is vital for system integrity and longevity․ Always verify compatibility with local plumbing codes․

Flexible Copper Pipe

Copper pipe size chart PDFs also cover flexible copper, typically used for short runs and connections where rigid pipe is impractical․ This type, often pre-insulated, simplifies installation around obstacles and reduces thermal conduction;

While offering convenience, flexible copper has limitations․ Charts detail allowable bend radii and maximum lengths to prevent kinking and maintain flow․ Understanding these parameters, alongside the dimensions of rigid types K, L, and M, is crucial for a complete plumbing system design․

Remember, even with the fascinating magnetic properties detailed in the Magnetic Copper PDF (384 Kb), proper sizing – guided by the chart – remains paramount․ As of December 3rd, 2025, ensure the selected flexible copper meets pressure and temperature requirements․

Understanding Copper Pipe Nominal Size vs․ Actual Size

Copper pipe size chart PDFs clearly illustrate the difference between nominal and actual dimensions․ Nominal size, like “1/2 inch,” is a designation for identification, not the precise measurement․

The actual inside and outside diameters are smaller․ Charts provide these precise figures, essential for accurate fittings selection and avoiding leaks․ This discrepancy stems from the pipe’s wall thickness, which varies based on type and schedule (40 or 80);

Ignoring this distinction can lead to improper connections and system failures․ Even considering the intriguing magnetic properties detailed in the Magnetic Copper PDF (384 Kb), accurate sizing – referencing the chart – is vital․ As of December 3rd, 2025, always verify actual dimensions before installation․

Copper Pipe Schedule (Schedule 40 vs․ Schedule 80)

Copper pipe size chart PDFs detail two primary schedules: 40 and 80, indicating wall thickness․ Schedule 40 is standard for residential water supply lines, offering a balance of cost and durability․

Schedule 80 features a thicker wall, providing greater pressure resistance and suitability for industrial applications or high-demand systems․ The charts specify the exact wall thickness and corresponding dimensions for each size and schedule․

Choosing the correct schedule is crucial; over-specifying increases cost, while under-specifying risks failure․ Remember, even considering the unusual magnetic interactions described in the Magnetic Copper PDF (384 Kb), structural integrity, dictated by schedule, is paramount․ As of December 3rd, 2025, consult the chart for appropriate selection․

Copper Pipe Dimensions ― Key Measurements

Copper pipe size chart PDFs meticulously outline three critical dimensions: Outside Diameter (OD), Inside Diameter (ID), and Wall Thickness․ OD remains consistent for a given nominal pipe size, simplifying connections․

However, ID varies based on the pipe’s schedule (40 or 80), impacting flow rate․ Wall thickness directly correlates to schedule and pressure-bearing capacity․ These charts provide precise measurements, often in inches, for each pipe size․

Understanding these dimensions is vital for accurate fittings selection and system design․ Remember, even considering the intriguing magnetic properties detailed in the Magnetic Copper PDF (384 Kb), precise dimensional accuracy, as found in these charts, is essential for a reliable plumbing system․ Today, December 3rd, 2025, utilize these charts for optimal results․

Outside Diameter (OD)

Copper pipe size chart PDFs consistently demonstrate that Outside Diameter (OD) is a fixed measurement for each nominal pipe size․ This standardization is crucial for ensuring compatibility with fittings – regardless of the schedule (40 or 80), the OD remains constant․

For instance, ½ inch nominal pipe always has the same OD, facilitating easy connections․ This contrasts with the Inside Diameter (ID), which does change with schedule․ Charts clearly display OD values, typically in inches, allowing plumbers to select appropriate components․

Even when considering the unusual magnetic interactions described in the Magnetic Copper PDF (384 Kb), the consistent OD remains a fundamental aspect of copper piping systems․ Today, December 3rd, 2025, rely on these charts for accurate OD specifications․

Inside Diameter (ID)

Copper pipe size chart PDFs highlight that the Inside Diameter (ID) varies based on the pipe’s schedule – specifically, Schedule 40 versus Schedule 80․ Schedule 80 pipes possess thicker walls, consequently reducing the ID compared to Schedule 40 pipes of the same nominal size․

This difference is critical for flow rate calculations; a smaller ID restricts water or gas flow․ Charts meticulously list ID values for each nominal size and schedule, expressed in inches․ Understanding these values is paramount for proper system design․

Interestingly, even considering the magnetic properties detailed in the Magnetic Copper PDF (384 Kb), the ID remains a key factor in fluid dynamics․ Today, December 3rd, 2025, accurate ID selection, guided by these charts, ensures optimal performance․

Wall Thickness

Copper pipe size chart PDFs meticulously detail wall thickness, a crucial factor differentiating pipe schedules․ Schedule 40 copper boasts a thinner wall compared to the more robust Schedule 80․ This thickness, measured in thousandths of an inch, directly impacts a pipe’s pressure-handling capacity and durability․

Charts clearly display wall thickness values corresponding to each nominal pipe size and schedule․ Selecting the appropriate thickness is vital; Schedule 80 is preferred for higher-pressure applications or where greater physical protection is needed․

Even considering the unusual magnetic interactions described in the Magnetic Copper PDF (384 Kb), wall thickness remains a purely mechanical property․ Today, December 3rd, 2025, referencing these charts ensures correct material selection for safe and reliable plumbing or HVAC systems․

Copper Pipe Size Chart for Water Supply Lines

Copper pipe size chart PDFs dedicated to water supply lines prioritize flow rate and fixture unit requirements․ These charts typically categorize applications – hot, cold, or mixed water – and correlate them to appropriate pipe diameters․ Factors like the number of fixtures, pipe length, and elevation changes influence the optimal size selection․

Charts often present data based on gallons per minute (GPM) to ensure adequate water pressure at each outlet․ Today, December 3rd, 2025, remember that larger diameter pipes minimize friction loss and maintain consistent pressure․

While the Magnetic Copper PDF (384 Kb) explores unique properties, water supply sizing remains grounded in fluid dynamics․ Consulting these charts guarantees compliance with plumbing codes and efficient water distribution throughout a building․

Copper Pipe Size Chart for Gas Lines

Copper pipe size chart PDFs for gas lines are critically important, differing significantly from water supply charts due to the nature of gas․ These charts focus on British Thermal Units (BTUs) and the total gas demand of all connected appliances․ Proper sizing prevents insufficient gas flow, impacting appliance performance, and avoids dangerous situations․

Charts categorize gas types – natural gas, propane – and specify pipe diameters based on appliance BTU ratings and pipe run lengths․ Today, December 3rd, 2025, always prioritize safety and adhere to local codes when selecting gas pipe sizes․

Unlike the properties detailed in the Magnetic Copper PDF (384 Kb), gas line sizing demands precision․ Incorrect sizing can lead to pressure drops or, conversely, oversupply, creating a hazardous environment․ Professional installation is strongly recommended․

Copper Pipe Size Chart for HVAC Systems

Copper pipe size chart PDFs for HVAC systems are essential for efficient refrigerant and water circulation․ These charts differ from those for water or gas, focusing on factors like refrigerant type, system capacity (tons), and pipe length․ Proper sizing minimizes pressure drop, maximizing system efficiency and preventing compressor strain․

Charts typically detail pipe diameters for both suction and liquid lines, considering the specific refrigerant’s properties․ Today, December 3rd, 2025, remember that accurate sizing is crucial for optimal HVAC performance․

While copper isn’t magnetic – as detailed in the Magnetic Copper PDF (384 Kb) – its thermal conductivity is vital in HVAC applications․ Incorrect pipe sizing can lead to reduced cooling/heating capacity and increased energy consumption․ Professional HVAC technicians rely heavily on these charts․

Flow Rate and Copper Pipe Size

Determining the correct copper pipe size hinges directly on the required flow rate of the fluid—water, gas, or refrigerant—traveling through the system․ Copper pipe size chart PDFs provide data correlating flow rate (typically in gallons per minute or GPM) with pipe diameter and length․

Higher flow rates necessitate larger diameter pipes to maintain adequate velocity and minimize friction loss․ Conversely, excessively large pipes for low flow rates can be inefficient and costly․ Today, December 3rd, 2025, consider that even though copper isn’t magnetic (see Magnetic Copper PDF, 384 Kb), its smooth interior minimizes flow resistance․

Charts often include velocity recommendations to prevent erosion or noise․ Accurate flow rate calculations are paramount for system performance and longevity, ensuring optimal delivery and preventing issues like water hammer․

Pressure Drop Considerations

Copper pipe size chart PDFs don’t just show diameter; they implicitly address pressure drop – the reduction in water pressure as it moves through the piping system․ Longer pipe runs and numerous fittings (elbows, tees) contribute to increased friction and, therefore, greater pressure loss․

Selecting an appropriately sized pipe minimizes this drop, ensuring sufficient pressure reaches the fixture or appliance․ Charts often provide pressure drop data per 100 feet of pipe․ Today, December 3rd, 2025, remember that while copper isn’t attracted to magnets (refer to the Magnetic Copper PDF, 384 Kb), its smooth bore reduces frictional resistance․

Ignoring pressure drop can lead to inadequate water flow, especially on upper floors or at distant fixtures․ Careful consideration of these factors is crucial for a functional and efficient plumbing system․

Calculating Pipe Size Based on Flow Rate

Determining the correct copper pipe size hinges on calculating the required flow rate for your application․ Copper pipe size chart PDFs are invaluable tools, but understanding the underlying calculations is key․ First, estimate the gallons per minute (GPM) needed for each fixture – faucets, showers, appliances․

Then, consider the total equivalent length of the pipe run, including straight sections and fittings․ Using friction loss tables (often found within the PDF charts), you can determine the pressure drop for various pipe sizes at your calculated GPM․ Today, December 3rd, 2025, remember the Magnetic Copper PDF (384 Kb) highlights copper’s non-magnetic properties, impacting flow dynamics minimally․

Select a pipe size that delivers the necessary flow rate while keeping the pressure drop within acceptable limits․ Online calculators can simplify this process․

Using a Copper Pipe Size Chart PDF – Step-by-Step

Effectively utilizing a copper pipe size chart PDF involves a systematic approach․ First, identify your application – water, gas, or HVAC․ Locate the corresponding chart within the PDF․ Today, December 3rd, 2025, remember the Magnetic Copper PDF (384 Kb) details copper’s unique properties․

Next, determine your required flow rate (GPM) or fixture unit load․ Find this value on the chart’s vertical axis․ Then, move horizontally until you intersect with your desired pressure drop․ The intersection point indicates the appropriate pipe size․

Always double-check the chart’s notes regarding pipe schedule (40 or 80) and material type․ Confirm the chart’s source and date for accuracy․ Consider consulting a professional if unsure․

Where to Find Reliable Copper Pipe Size Chart PDFs

Locating trustworthy copper pipe size chart PDFs is crucial for accurate plumbing and HVAC installations․ Begin with manufacturer websites like Mueller and Genova, which often provide detailed charts specific to their products․ Today, December 3rd, 2025, remember the Magnetic Copper PDF (384 Kb) offers insights into copper’s behavior․

Industry standards organizations, such as ASTM, are excellent sources for standardized charts․ Reputable plumbing supply retailers may also offer downloadable PDFs․ Be cautious of unofficial sources; verify the chart’s origin and date․

Ensure the PDF is clearly labeled, includes relevant dimensions, and aligns with local plumbing codes․ Cross-reference information from multiple sources to confirm accuracy before making critical decisions․

Manufacturer Websites (e․g․, Mueller, Genova)

Mueller and Genova, leading copper pipe manufacturers, offer comprehensive copper pipe size chart PDFs directly on their websites․ These charts are specifically tailored to their product lines, ensuring accuracy for their fittings and pipes․ Today, December 3rd, 2025, accessing these resources provides the most up-to-date information․

These PDFs typically include detailed dimensions – outside diameter (OD), inside diameter (ID), and wall thickness – for various pipe sizes and schedules․ They often categorize charts by pipe type (K, L, M) and application (water, gas, HVAC)․

Remember to check for the latest revision date, as specifications can change․ Don’t forget the Magnetic Copper PDF (384 Kb) for related insights!

Industry Standards Organizations (e․g․, ASTM)

ASTM International, a globally recognized standards organization, publishes detailed specifications for copper pipe, influencing copper pipe size chart PDFs․ While ASTM doesn’t directly offer downloadable charts in a single PDF, their standards (like ASTM B88) define the dimensional requirements manufacturers must adhere to․

These standards are the foundation for creating accurate sizing guides․ Understanding ASTM specifications ensures compliance and safety in plumbing and HVAC systems․ Today, December 3rd, 2025, referencing these standards provides a definitive source for pipe dimensions and material properties․

Accessing ASTM standards often requires a subscription or purchase․ However, manufacturers frequently base their charts on these standards, so checking their documentation is a practical alternative․ Remember the Magnetic Copper PDF (384 Kb) for related material science!

Decoding Information Within a Copper Pipe Size Chart PDF

A copper pipe size chart PDF isn’t just numbers; it’s a technical document․ Key elements include nominal pipe size (NPS), which indicates the approximate inside diameter, and actual dimensions like outside diameter (OD) and inside diameter (ID)․ Pay close attention to wall thickness, denoted as Schedule 40 or Schedule 80, impacting pressure capacity․

Charts also list weight per foot, crucial for material estimation․ Today, December 3rd, 2025, understanding flow rate capacity at various pipe sizes is vital for system design․ Remember to cross-reference with pressure drop calculations․ Don’t overlook color codes indicating pipe type (e․g․, green for medical gas)․

Furthermore, consider the Magnetic Copper PDF (384 Kb) for understanding material properties․ Accurate interpretation ensures correct pipe selection for your application, preventing costly errors and ensuring system integrity․

Copper Pipe Weight per Foot Chart

Understanding copper pipe weight per foot is critical for accurate project costing and material handling․ A typical copper pipe size chart PDF will detail this information, varying based on both nominal pipe size and schedule (40 or 80)․ For instance, ½ inch Type L copper weighs approximately 0․19 lbs/ft, while 1 inch Type K can weigh around 0․88 lbs/ft․

These figures are essential for calculating total material weight, shipping costs, and structural support requirements․ Today, December 3rd, 2025, remember that weight increases with both diameter and wall thickness; Referencing a reliable chart, alongside the Magnetic Copper PDF (384 Kb), ensures precise estimations․

Always verify the chart’s specifications (copper alloy, schedule) to guarantee accuracy․ Proper weight calculation minimizes waste and ensures a successful plumbing or HVAC installation․

Copper Pipe Color Codes

While copper naturally exhibits a reddish-brown hue, color coding isn’t a standardized practice for identifying pipe size within a copper pipe size chart PDF․ However, color variations can indicate different manufacturing processes or coatings․ Greenish hues often signify oxidation, a natural process, but shouldn’t impact functionality․

Manufacturers sometimes use colored markings for identification, but these aren’t universal․ Today, December 3rd, 2025, relying on markings alone is unreliable; always verify size using proper measuring tools and referencing the chart․ The Magnetic Copper PDF (384 Kb) demonstrates how external factors can alter appearance․

Focus on the markings indicating type (K, L, M) and schedule (40, 80) as detailed in the PDF chart․ Consistent color isn’t a substitute for accurate size verification during installation․

Soldering and Brazing Considerations Based on Pipe Size

Selecting the correct soldering or brazing technique is crucial when working with copper pipes, and is often detailed within a copper pipe size chart PDF․ Smaller diameter pipes (½” and ¾”) are typically soldered using standard lead-free solder․ Larger diameters (1” and above) often benefit from brazing, offering stronger joints and higher temperature resistance․

Today, December 3rd, 2025, heat control is paramount․ Larger pipes require more heat input, demanding skilled technique to prevent overheating and potential damage․ The Magnetic Copper PDF (384 Kb) illustrates how heat affects metal properties․ Always consult the chart for recommended filler metals based on pipe size and application․

Proper flux application and joint preparation are vital for successful connections, regardless of size․ Ensure adequate ventilation during these processes, and follow all safety guidelines․

Tools Required for Working with Copper Pipe

Successfully working with copper pipe, guided by a copper pipe size chart PDF, necessitates a specific toolkit․ Essential tools include a pipe cutter – wheel or rotary – for clean, burr-free cuts․ Deburring tools are vital for removing internal shavings․ Flaring tools are needed for creating flared connections, while a propane or MAPP gas torch is crucial for soldering or brazing․

Today, December 3rd, 2025, remember flux brushes, solder or brazing rods, and safety glasses are non-negotiable․ The Magnetic Copper PDF (384 Kb) highlights metal reactivity․ Pipe wrenches provide grip for tightening fittings, and reamers ensure proper fitting alignment․ A tubing bender is essential for creating smooth bends without kinking․

Having the right tools, alongside your size chart, ensures efficient and professional results․

Safety Precautions When Working with Copper Pipe

Prioritizing safety is paramount when working with copper pipe, even while referencing a detailed copper pipe size chart PDF․ Always wear safety glasses to protect your eyes from flying debris during cutting and deburring․ When soldering or brazing, utilize appropriate gloves to prevent burns from the torch and hot pipes․

Today, December 3rd, 2025, ensure adequate ventilation to avoid inhaling fumes․ Be mindful of flammable materials near the open flame․ The Magnetic Copper PDF (384 Kb) details metal properties․ Never work with pressurized pipes without fully depressurizing them first․

Proper handling of tools, like pipe cutters and torches, is crucial․ Store tools safely when not in use․ Following these precautions minimizes risks and ensures a safe working environment․

Common Mistakes to Avoid When Selecting Copper Pipe Size

A frequent error is neglecting future flow demands when consulting a copper pipe size chart PDF․ Always account for potential additions to plumbing fixtures․ Another mistake is confusing nominal pipe size with actual inside diameter – the chart clarifies these distinctions․

Ignoring pressure drop calculations can lead to insufficient water pressure at fixtures․ Today, December 3rd, 2025, remember that longer pipe runs require larger diameters․ Failing to consider the type of fittings used (elbows, tees) adds resistance to flow․

Don’t overlook the impact of water heater size and flow rate․ The Magnetic Copper PDF (384 Kb) details material properties․ Always double-check your calculations and consult a professional if unsure․ Accurate pipe sizing prevents costly rework and ensures optimal system performance․

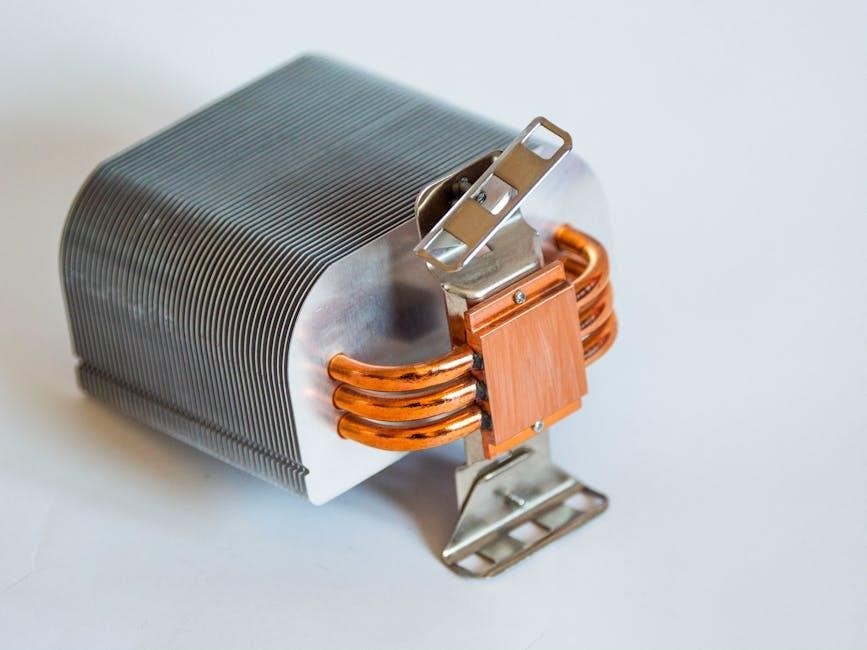

Magnetic Properties of Copper and Related PDFs

Pure copper is diamagnetic, meaning it’s weakly repelled by a magnetic field – a characteristic often overlooked when reviewing a copper pipe size chart PDF․ However, alloys and impurities can introduce slight magnetic responses․

Interestingly, despite not being ferromagnetic, magnets can appear to interact with copper due to eddy currents induced within the metal․ Today, December 3rd, 2025, the Magnetic Copper PDF (384 Kb) explores this phenomenon in detail, requiring Adobe Acrobat for access․

This interaction isn’t a true attraction but a result of Lenz’s Law․ While irrelevant to pipe sizing itself, understanding this property is crucial for non-destructive testing methods sometimes used to assess pipe integrity․ Always refer to reliable sources for accurate material data․

Resources for Further Information on Copper Piping

Beyond a standard copper pipe size chart PDF, numerous resources offer in-depth knowledge․ The Copper Development Association (CDA) provides extensive technical data, installation guides, and design information for various applications;

Manufacturer websites like Mueller and Genova (mentioned in finding reliable PDFs) offer specific product details, including dimensional data and flow rate calculations․ Industry standards from organizations like ASTM are crucial for ensuring compliance and quality․

Today, December 3rd, 2025, remember the Magnetic Copper PDF (384 Kb) details unique properties, though less directly related to sizing․ Online plumbing forums and professional trade associations also provide valuable insights and practical advice․ Always prioritize information from reputable sources․